Product Description

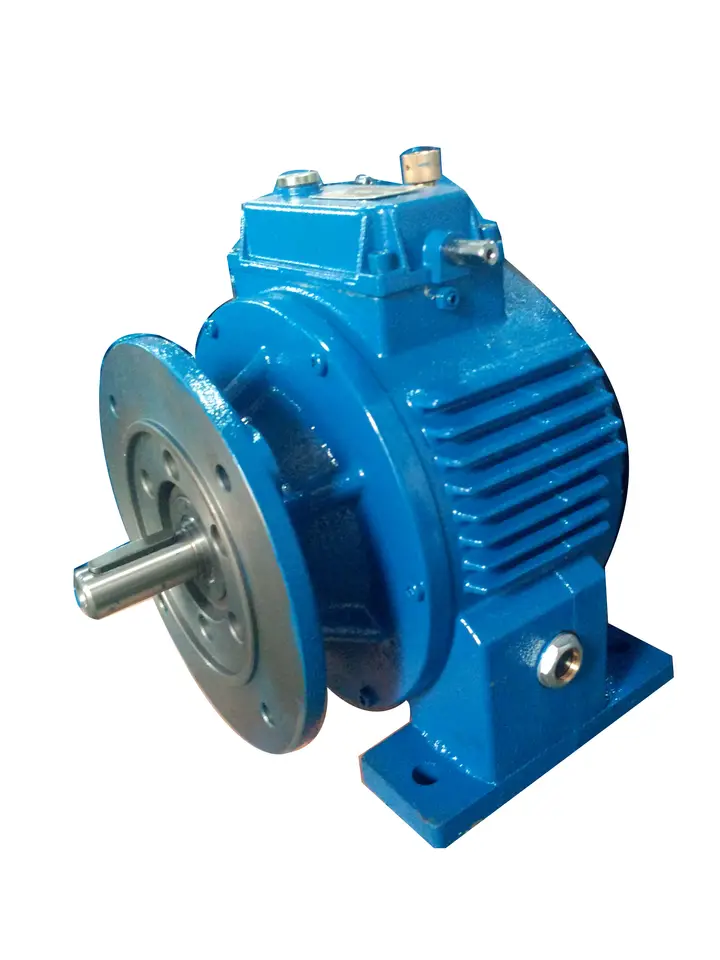

NMRV WORM GEARBOX

Gearbox Data Summary

| Model | Power (kW) |

Transmission ratio (i) |

Rotate speed (RPM) |

Output torque (N. m) |

| RV30-150 | 0.06-15 | 5-100 | 14-280 | 5-1800 |

Features

- Its appearance is “square box” structure, with beautiful appearance, small volume, rapid heat dispersion, and flexible use and installation.

- Worm and gear pairs adopt precision machining, manufacturing, and gearing test, to guarantee balanced transmission, low temperature rise, small noise, high efficiency, and long life.

- Input and output parts adopt precise and neat processing, no rust and high end.

- The product adopts superior bearing transmission parts and sealing elements, durable and no-leakage.

- Continuously variable transmission and worm gear reducer use cooperatively, which can adjust output rotate speed in loads and realize continuously variable transmission.

Application

Products are widely used in ceramic, glass, food, metallurgy, beer & drink, printing and dyeing, textile, petrochemical engineering, warehouse logistics, wood-working machine, environmental protection equipment, printing and packaging, pharmacy, and leather.

FAQ

Q: What is your MOQ of this item?

A: 5PCS. For the first time cooperation, we accept trial sample order.

Q: What’s your payment terms?

A: 30% T/T deposit, 70% balance before shipment or L/C at sight.

Q: What’s the delivery time?

A: 30 days after receiving your L/C or T/T deposit.

Q: How long is your warranty?

A: 12 months from leave the port.

Factory

Our Office Block

Company Staff

| Application: | Industry |

|---|---|

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Manufacturing Method: | Rolling Gear |

| Manipulate Way: | Semi-Automatic Manipulation |

| Changes Way: | Stepped |

| Customization: |

Available

| Customized Request |

|---|

Variable Gearbox: Function and Operation

A variable gearbox is a transmission system that allows for continuously adjustable gear ratios, enabling optimal power transfer across various speeds. It employs mechanisms like CVTs (Continuously Variable Transmissions) or e-CVTs (Electronically Controlled CVTs) that use belts, pulleys, or gears to maintain a seamless range of gear ratios without discrete shifts. This design offers smooth acceleration, improved fuel efficiency, and adaptive performance. By altering the effective gear ratio based on the engine’s power and vehicle’s speed, a variable gearbox ensures the engine operates within its

Effect of Different Load Conditions on a Variable Gearbox

The performance of a variable gearbox can be significantly influenced by various load conditions. Here’s how different load conditions can affect a variable gearbox:

- Light Loads: Under light load conditions, a variable gearbox may operate at lower torque levels. This can lead to higher efficiency and reduced wear and tear on components, resulting in smoother operation and potentially improved fuel efficiency.

- Normal Loads: Operating within the designed load range of the gearbox ensures optimal performance and efficiency. The gearbox can adapt to changes in load and provide the appropriate gear ratio for efficient power transmission.

- Heavy

Operation of a Hydrostatic Variable Gearbox in Heavy Machinery

A hydrostatic variable gearbox, commonly found in heavy machinery, operates using a hydraulic transmission system to control speed and torque:

The key components of a hydrostatic variable gearbox include:

- Hydraulic Pump: Converts mechanical energy from the engine into hydraulic pressure.

- Hydraulic Motor: Converts hydraulic pressure back into mechanical energy to drive the machinery.

- Variable Displacement Pump: Allows for the adjustment of hydraulic fluid flow rate.

- Control Valves: Regulate the flow of hydraulic fluid to control the speed and direction of the machinery.

The gearbox operates as follows:

- The hydraulic pump draws in hydraulic fluid from a reservoir and pressurizes it.

- The pressurized hydraulic fluid is directed to the hydraulic motor, which converts it into mechanical energy to drive the machinery.

- The variable displacement pump allows the operator to adjust the amount of hydraulic fluid flow, thereby controlling the speed of the machinery.

- The control valves direct the flow of hydraulic fluid to control the direction of movement (forward or reverse) and the speed.

This system offers excellent control over the machinery’s speed and torque output. By adjusting the hydraulic fluid flow rate and the angle of the hydraulic motor’s swashplate, operators can achieve precise control over the heavy machinery’s movement and performance.

Loads:

When subjected to heavy loads, a variable gearbox may experience increased stress and higher torque demands. While the gearbox can adapt and provide higher torque output, it may also generate more heat and experience greater wear, potentially affecting its longevity if not properly managed. - Variable Loads: In applications with varying loads, a well-designed variable gearbox can provide continuous adjustment of the gear ratio to match the changing demands. This flexibility can enhance overall efficiency and prevent strain on the gearbox.

- Overloads: Operating the gearbox beyond its rated capacity or experiencing sudden spikes in load can lead to excessive wear, reduced efficiency, and potential overheating. It’s important to avoid overloading the gearbox to ensure its longevity.

In summary, different load conditions can impact the performance, efficiency, and durability of a variable gearbox. Properly managing and selecting the appropriate gear ratios for specific load conditions can help optimize its operation and maximize its lifespan.

optimal efficiency range, enhancing overall driving experience and efficiency.

editor by CX 2023-08-30