Product Description

Specification OF PTO GEARBOX —Speedway:

We developed and produced many tractor spare parts for European Tractors .

Tractor Model we can supply: B1500/1400,B5000,B6000, B7000, TU1400, TX1400, TX1500, YM F1401, YM1400 ETC.

The parts for example: Gearboxes, Tyres, rim Jante, Kit coupling KB-TX 3 point linkage. Exhaust pipe Steering wheel. Kit coupling YM F14/F15, gear shaft, PTO shaft, PTO cardan, key, regulator ect.

Most of the spare parts are with stock. If you are interested in, please feel easy to contact me.

Other relevant parts for cars or machinery we have made in our workshop are as follows:

Drive shaft parts and assemblies,

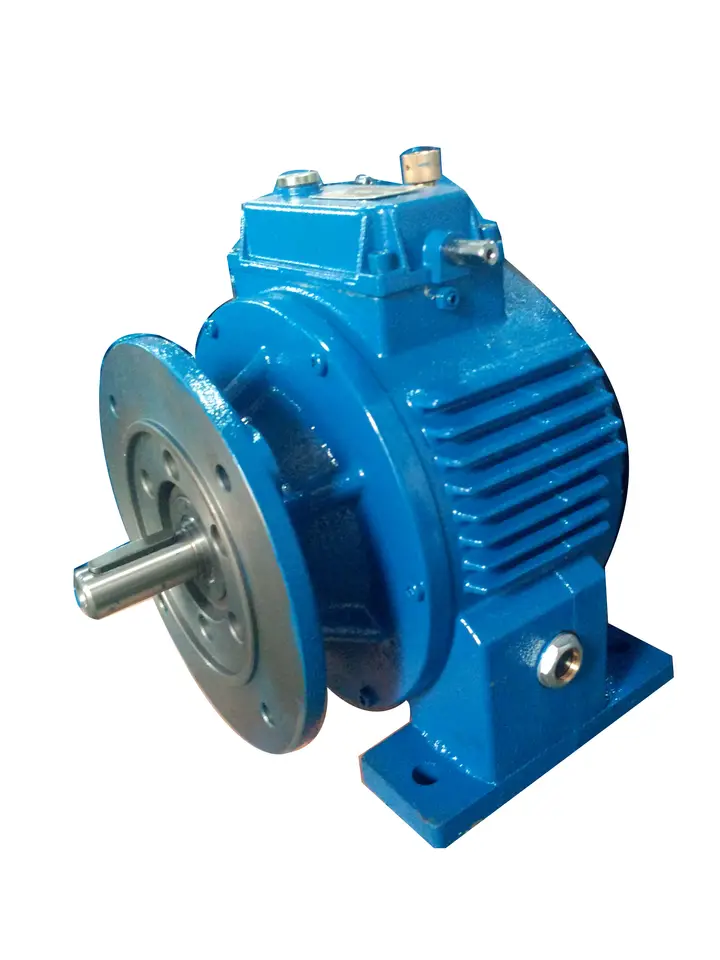

PTO GEARBOX,

Universal joint parts and assemblies,

PTO drive shafts,

Spline shafts,

Slip yokes,

Weld yokes,

Flange yokes,

Steering columns,

Connecting rods,

etc.

Product Description

Pto Drive Gearbox Item:

|

Name |

1.92:1 Agricultural PTO Gearbox for 20-70hp Tractor Reducer for Rotary Cultivator |

|

Advantage |

No matter you’re cutting brush or mowing pastures, we has the rotary cutter gearbox to fit your |

|

Material available |

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

|

Surface treatment

|

Blacking, galvanization, chroming, electrophoresis, color painting, … |

|

Heat treatment

|

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, …

|

Company Profile

Certifications

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Type: | Planetary Gear Box |

| Product Name: | 1.92:1 Speed Reducer & Gearboxes |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

Adjusting Gear Ratio in a Variable Gearbox

In a variable gearbox, adjusting the gear ratio is typically achieved through mechanisms like Continuously Variable Transmissions (CVTs). CVTs use various designs, such as pulleys with adjustable diameters or expanding/contracting belts, to vary the effective gear ratio continuously. By changing the effective diameters of the pulleys or the distance between the belt’s contact points, the gear ratio can be adjusted smoothly, allowing the engine to operate at its most efficient speed under different load conditions. Other variable transmission systems may use different principles, but the goal is to provide seamless and continuous adjustment of the gear ratio.

Maintaining and Servicing a Variable Gearbox

Maintaining and servicing a variable gearbox, such as a Continuously Variable Transmission (CVT), is essential to ensure optimal performance and longevity. Here are the steps involved:

- Regular Inspections: Perform routine visual inspections of the gearbox to check for leaks, damage, or unusual wear. Address any issues promptly.

- Fluid Level Check: CVTs use special transmission fluid. Check the fluid level according to the manufacturer’s guidelines and top up if necessary.

- Fluid Change: Over time, transmission fluid can deteriorate. Follow the recommended fluid change intervals to maintain proper lubrication and cooling.

- Belt Inspection: In belt-driven CVTs, inspect the belt for signs of wear, cracking, or stretching. Replace the belt if it shows significant damage.

- Belt Adjustment: Some CVTs have adjustable belts. Follow the manufacturer’s instructions to ensure proper tension for optimal performance.

- Software Updates: If the variable gearbox is electronically controlled, stay updated with the latest software patches or updates from the manufacturer.

- Professional Service: For more complex maintenance tasks, such as internal inspections or repairs, consult a professional technician with experience in variable gearboxes.

- Follow Manufacturer’s Guidelines: Always adhere to the manufacturer’s recommended maintenance schedule and guidelines for your specific gearbox model.

Proper maintenance and timely servicing can help extend the lifespan of the variable gearbox and ensure that your vehicle or equipment operates smoothly and efficiently.

Improving Energy Efficiency with a Variable Gearbox

A variable gearbox, like a Continuously Variable Transmission (CVT), can enhance energy efficiency by allowing the engine to operate at its optimal RPM range, irrespective of the vehicle’s speed. This eliminates inefficient gear changes and reduces the engine’s workload during acceleration. The CVT’s stepless gear ratio adjustments enable the engine to maintain a constant and efficient power delivery, resulting in better fuel economy. Additionally, the CVT’s ability to adapt to different driving conditions ensures that the engine operates at the most efficient RPM, further contributing to fuel savings.

editor by CX 2024-04-04