Product Description

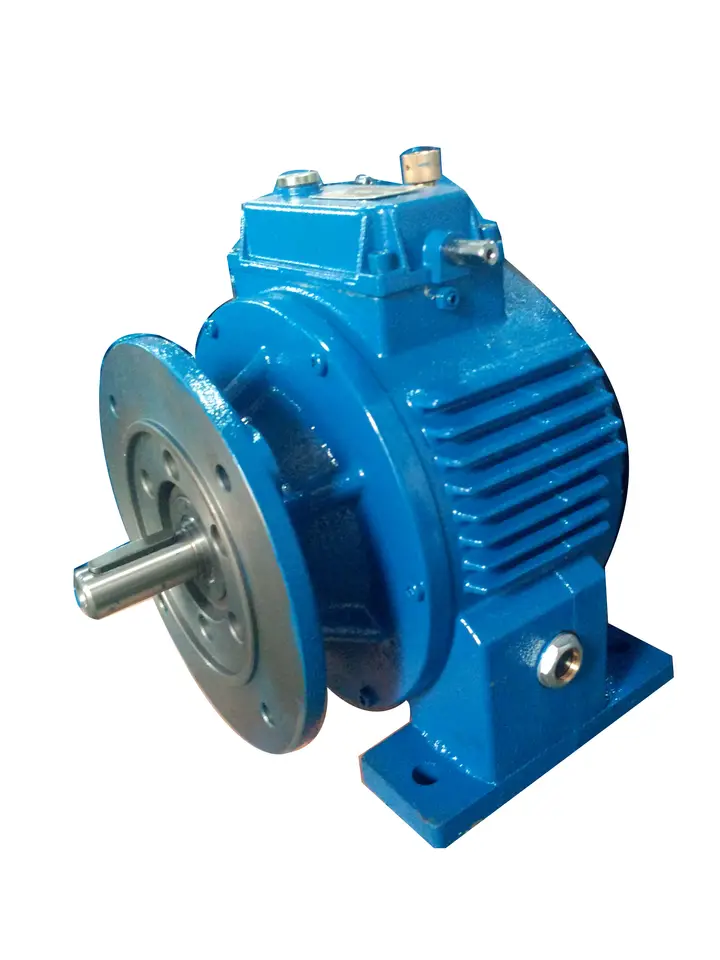

K Series Helical Bevel Foot Mounted Gearbox with Variable Frequency Braking Motor with Flange Connection

Product Description

K series gearbox is 1 kind of Helical Bevel type gearbox ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,low energy consumption, superior performance . The hard tooth surface gear use the high quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow characters : Stable transmission , low noise and temperature ,high loading ,long working life. Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics,which widely use for industry equipment of metallurgy ,Building Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,etc.

1.Technical data:

| Product Name | K Series Helical Bevel Foot Mounted Gearbox with Variable Frequency Braking Motor with Flange Connection |

| Gear material | 20CrMnTi alloy steel |

| Color | Blue Silver Customerized |

| Case Material | Cast iron HT200 |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CHINAMFG ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Backlash | ≤20Arcmin |

2. Installation type and output mode:

bottom seated type and large and small flange type installation, CHINAMFG shaft output.

3. Input mode:

direct motor, shaft input and connecting flange input.

4. Reduction ratio:

5.36~17396

5. Average efficiency:

95%

6.Technical parameters:

Coaxial output

Power: 0.12KW~200KW

Torque: 10N · m ~ 50000N · m

Output speed: 7 ~ 415r/min

7. Model of R series reducer:

K37, 47, 57, 67, 77, 87, 97, 107,127, 157

Detailed Photos

Certifications

Packaging & Shipping

Installation Instructions

Company Profile

< ABOUT TILI

< WORKSHOP

< QUALITY CONTROL

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Advantages of Using a Variable Gearbox in Automotive Applications

Variable gearboxes, particularly Continuously Variable Transmissions (CVTs), offer several advantages in automotive applications:

- Improved Fuel Efficiency: CVTs can continuously adjust the gear ratio to keep the engine operating at its most efficient point, leading to better fuel economy.

- Smooth Acceleration: CVTs provide seamless acceleration without the need for distinct gear shifts, resulting in a smoother driving experience.

- Optimized Performance: Variable gearboxes can adapt to changing road conditions and driving styles, providing optimal performance and power delivery.

- Reduced Emissions: The efficient operation of CVTs can lead to reduced greenhouse gas emissions, contributing to environmental sustainability.

- Enhanced Driving Comfort: The absence of gear shifts in CVTs eliminates jerks and jolts during acceleration, leading to a more comfortable ride.

- Flexible Power Delivery: Variable gearboxes allow engines to operate at their most efficient speed, enabling quick response and power delivery as needed.

- Adaptive Driving: CVTs can adapt to changing driving conditions, such as uphill or downhill driving, by adjusting the gear ratio accordingly.

Overall, the use of a variable gearbox in automotive applications can result in improved performance, fuel efficiency, and driving comfort.

Effect of Different Load Conditions on a Variable Gearbox

The performance of a variable gearbox can be significantly influenced by various load conditions. Here’s how different load conditions can affect a variable gearbox:

- Light Loads: Under light load conditions, a variable gearbox may operate at lower torque levels. This can lead to higher efficiency and reduced wear and tear on components, resulting in smoother operation and potentially improved fuel efficiency.

- Normal Loads: Operating within the designed load range of the gearbox ensures optimal performance and efficiency. The gearbox can adapt to changes in load and provide the appropriate gear ratio for efficient power transmission.

- Heavy Loads: When subjected to heavy loads, a variable gearbox may experience increased stress and higher torque demands. While the gearbox can adapt and provide higher torque output, it may also generate more heat and experience greater wear, potentially affecting its longevity if not properly managed.

- Variable Loads: In applications with varying loads, a well-designed variable gearbox can provide continuous adjustment of the gear ratio to match the changing demands. This flexibility can enhance overall efficiency and prevent strain on the gearbox.

- Overloads: Operating the gearbox beyond its rated capacity or experiencing sudden spikes in load can lead to excessive wear, reduced efficiency, and potential overheating. It’s important to avoid overloading the gearbox to ensure its longevity.

In summary, different load conditions can impact the performance, efficiency, and durability of a variable gearbox. Properly managing and selecting the appropriate gear ratios for specific load conditions can help optimize its operation and maximize its lifespan.

Improving Energy Efficiency with a Variable Gearbox

A variable gearbox, like a Continuously Variable Transmission (CVT), can enhance energy efficiency by allowing the engine to operate at its optimal RPM range, irrespective of the vehicle’s speed. This eliminates inefficient gear changes and reduces the engine’s workload during acceleration. The CVT’s stepless gear ratio adjustments enable the engine to maintain a constant and efficient power delivery, resulting in better fuel economy. Additionally, the CVT’s ability to adapt to different driving conditions ensures that the engine operates at the most efficient RPM, further contributing to fuel savings.

editor by CX 2024-04-26