Product Description

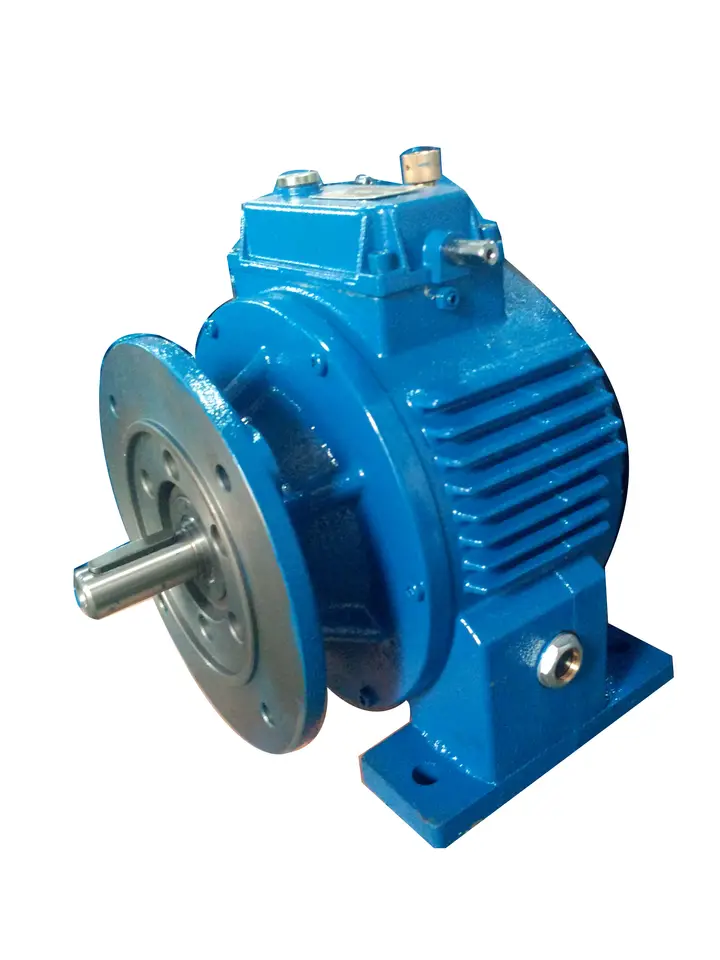

SF Series B5 Flange Mounted Helical-worm Gearbox with Variable Frequency Braking Motor with Flange Connection

S series: right-angle speed reduction gearing composed by helical gears, worms, and gears, optimized and designed according to international standard.

High precision, high efficiency, fine classification in transmission ratio, wide range, large transmission torque, reliable performance, low noise, flexible installation, and convenient use and maintenance.

They are widely used in various low-speed transmissions, which are general basic parts of mechanical transmission.The gear ratios afforded by the helical-worm gear stage and the low noise levels during operation make these gear motor ideal low-cost solutions for simple applications.

1.Technical data:

| Product Name | SF Series B5 Flange Mounted Helical-worm Gearbox with Variable Frequency Braking Motor with Flange Connection |

| Gear material | 20CrMnTi alloy steel |

| Color | Blue Silver Customerized |

| Case Material | Cast iron HT200 |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CHINAMFG ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 89% (depends on the transmission stage) |

| Backlash | ≤20Arcmin |

2. Installation type and output mode:

bottom seated type and large and small flange type installation, CHINAMFG shaft output.

3. Input mode:

direct motor, shaft input and connecting flange input.

4. Reduction ratio:

7.75~12901, S,R combination up to 33918.

5.Technical parameters:

Coaxial output

Motor Power: 0.12kw-30kw

Torque: 1.4N · m ~ 23200N · m

Output speed: 0.06 ~ 374r/min

6. Model of R series reducer:

SF37, 47, 57, 67, 77, 87, 97

Detailed Photos

Certifications

Packaging & Shipping

Installation Instructions

Company Profile

< ABOUT TILI

< WORKSHOP

< QUALITY CONTROL

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Controlling Speed and Torque Output in a Variable Gearbox

In a variable gearbox, the speed and torque output are controlled by adjusting the transmission’s gear ratio. This is achieved through the manipulation of the pulley diameters in a Continuously Variable Transmission (CVT) or the swivel angle of the vanes in a hydrostatic transmission.

In a CVT, the pulley system consists of a primary pulley connected to the engine and a secondary pulley connected to the output shaft. By changing the effective diameter of these pulleys using hydraulic pressure or mechanical mechanisms, the gear ratio can be continuously adjusted. As the primary pulley diameter increases, the secondary pulley diameter decreases, and vice versa. This change in pulley diameters alters the gear ratio, affecting the speed and torque output.

In a hydrostatic transmission, the speed and torque output are controlled by adjusting the swivel angle of the vanes in the hydraulic pump and motor. When the swivel angle changes, the volume of fluid being pumped between the two components also changes, affecting the output speed and torque. This type of transmission offers stepless control of the gear ratio, making it suitable for applications that require precise speed and torque adjustments.

Lubrication Requirements for a Variable Gearbox

A variable gearbox, like any other gearbox, requires proper lubrication to ensure smooth operation and longevity. The type of lubrication needed depends on the specific design and components of the gearbox. Here’s what you should consider:

- Lubricant Type: The lubricant used should be compatible with the materials and components within the gearbox. High-quality transmission fluids or gear oils are commonly used for variable gearboxes.

- Viscosity: The viscosity of the lubricant is crucial for maintaining proper lubrication under different temperature conditions. The manufacturer’s recommendations or specifications should guide your choice of lubricant viscosity.

- Friction and Wear Protection: Variable gearboxes often have components that experience varying levels of friction. The lubricant should provide good wear protection and minimize friction to ensure efficient operation and minimize heat generation.

- Cooling Properties: Some variable gearboxes, especially those in heavy-duty applications, can generate significant heat. The lubricant should have effective cooling properties to dissipate heat and prevent overheating.

- Seal Compatibility: The lubricant should be compatible with any seals or gaskets in the gearbox, ensuring they remain effective in preventing fluid leaks.

- Regular Maintenance: Regular oil changes and maintenance are essential to keep the lubricant in optimal condition. Follow the manufacturer’s recommended maintenance schedule for oil changes and inspections.

It’s important to refer to the vehicle or equipment manufacturer’s recommendations for the specific lubricant type, viscosity, and maintenance schedule that best suit your variable gearbox. Proper lubrication will contribute to the gearbox’s smooth operation, efficiency, and overall longevity.

Variable Gearbox: Function and Operation

A variable gearbox is a transmission system that allows for continuously adjustable gear ratios, enabling optimal power transfer across various speeds. It employs mechanisms like CVTs (Continuously Variable Transmissions) or e-CVTs (Electronically Controlled CVTs) that use belts, pulleys, or gears to maintain a seamless range of gear ratios without discrete shifts. This design offers smooth acceleration, improved fuel efficiency, and adaptive performance. By altering the effective gear ratio based on the engine’s power and vehicle’s speed, a variable gearbox ensures the engine operates within its optimal efficiency range, enhancing overall driving experience and efficiency.

editor by CX 2024-04-23