Product Description

Product Description

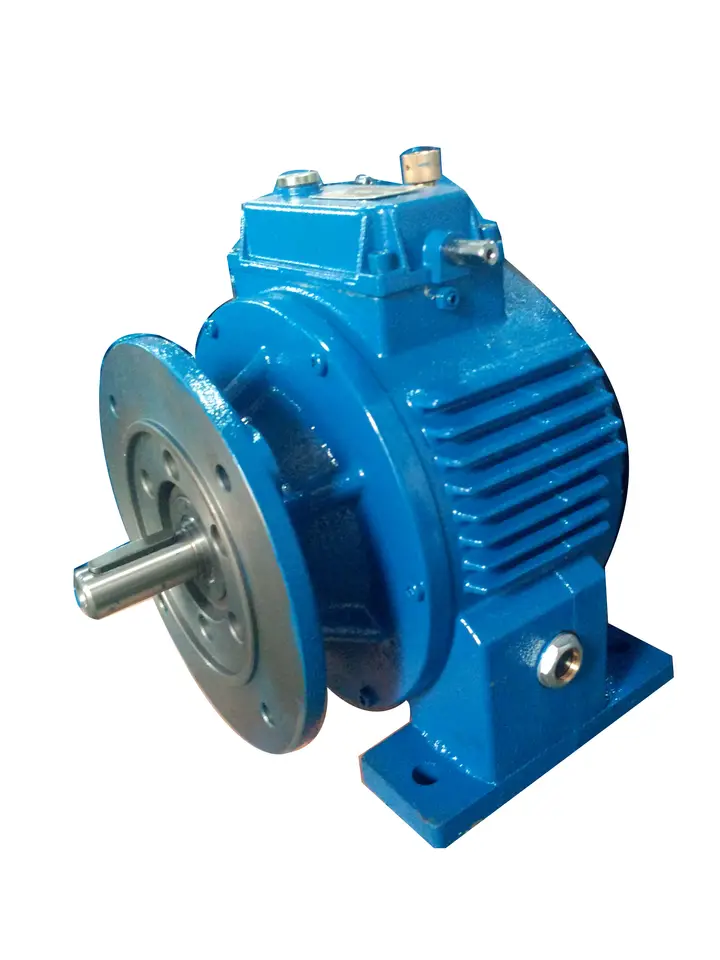

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of “Platform Product, Application Design and Professional Service”.

CHINAMFG have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for CHINAMFG With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of CHINAMFG

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Ceramic |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizotal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary Conedisk Friction Type |

| Step: | Stepless |

| Customization: |

Available

| Customized Request |

|---|

Role of Continuously Variable Transmission (CVT) Gearbox

The role of a Continuously Variable Transmission (CVT) gearbox is to provide a seamless and infinite range of gear ratios to optimize engine performance and fuel efficiency. Unlike traditional gearboxes with fixed gears, a CVT uses a belt or chain running between two variable-sized pulleys. By adjusting the pulley diameters, the gear ratio can be continuously varied to match the engine’s power output and the vehicle’s speed.

CVTs are designed to keep the engine operating at its most efficient RPM range, resulting in better fuel economy and smoother acceleration. They eliminate the need for discrete gear shifts, providing a smooth and uninterrupted power delivery. CVTs are commonly used in automobiles, especially in hybrid vehicles, compact cars, and scooters, where optimizing engine efficiency and providing a comfortable driving experience are essential.

Potential Drawbacks and Limitations of Using a Variable Gearbox

While variable gearboxes offer many benefits, they also come with certain drawbacks and limitations:

- Complexity: Variable gearboxes can be more complex than traditional gearboxes, which can lead to increased manufacturing and maintenance costs.

- Learning Curve: Users, especially drivers new to variable gearboxes, may need time to adjust to the continuously changing gear ratios and driving characteristics.

- Efficiency at Extremes: Some variable gearboxes may not perform optimally at extreme power levels or high-speed applications compared to fixed-ratio gearboxes.

- Heat Generation: In some cases, variable gearboxes can generate more heat due to the continuous slipping of components, which may require additional cooling measures.

- Manufacturing Complexity: The design and manufacturing of variable gearboxes can be more intricate, leading to higher initial costs for production.

- Wear and Tear: The components involved in variable gearboxes, such as belts and pulleys, can experience wear and tear over time and may need more frequent replacement.

- Compatibility: Variable gearboxes may not be compatible with all types of engines or applications, limiting their versatility.

- Maintenance Requirements: Variable gearboxes may require specialized maintenance procedures and specific fluids, adding complexity to servicing.

- Environmental Concerns: Some variable gearboxes may use materials or technologies that have environmental implications, such as the disposal of transmission fluid.

It’s important to weigh these limitations against the advantages of variable gearboxes to determine whether they are the right choice for a particular application.

Improving Energy Efficiency with a Variable Gearbox

A variable gearbox, like a Continuously Variable Transmission (CVT), can enhance energy efficiency by allowing the engine to operate at its optimal RPM range, irrespective of the vehicle’s speed. This eliminates inefficient gear changes and reduces the engine’s workload during acceleration. The CVT’s stepless gear ratio adjustments enable the engine to maintain a constant and efficient power delivery, resulting in better fuel economy. Additionally, the CVT’s ability to adapt to different driving conditions ensures that the engine operates at the most efficient RPM, further contributing to fuel savings.

editor by CX 2024-04-03