Product Description

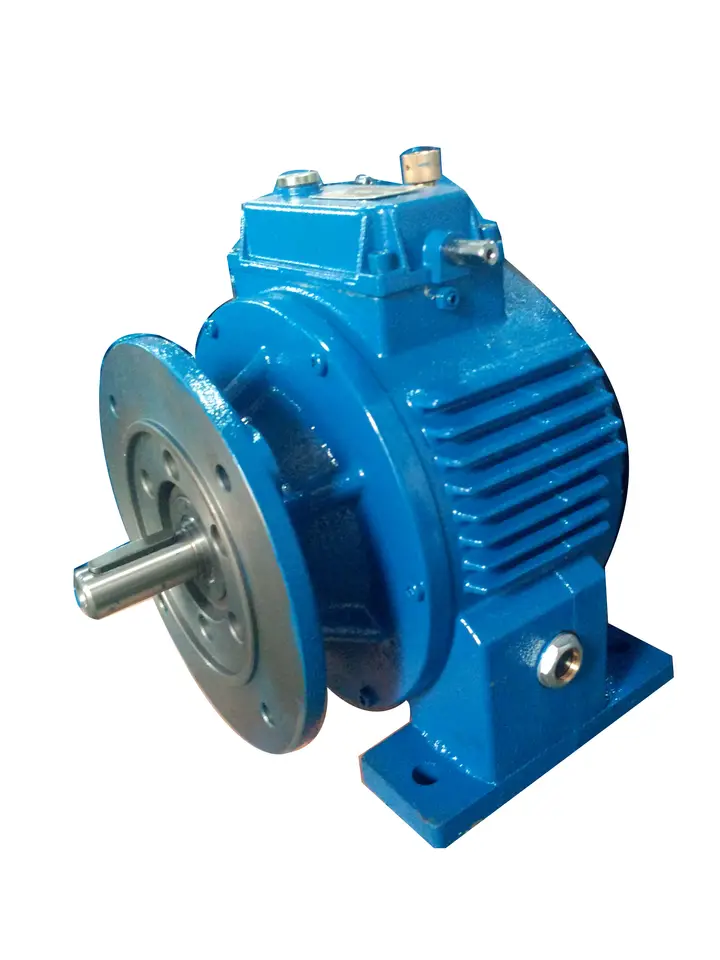

R47 Right Angle Helical Gear Reductor Belt Conveyor Drives Speed Reducer helical Gearbox for Textile Industry

Detailed Photos

Product Parameters

Products Description

R Series Helical Speed Reducers

R series helical gear reducer has high technological content; it adopts hardened gear surface design, which is reliable and durable and has high overload capacity.

It has the following characteristics

1,R series helical gear reducer is manufactured in accordance with international technical requirements, meeting the technical

requirements of most countries in the world.

2,The design of R series helical gear reducer plays a space-saving, high overload capacity.

3, R series helical gear reducer has low energy consumption, superior performance and high efficiency of more than 95%;

4,R series helical gear reducer has low vibration, low noise, and high energy saving;

5,R series helical gear reducer is made of high quality forged steel material, steel cast iron case, and the surface of gear is heat-treated by high frequency; reliable and durableTranslated with DeepL

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Types of Variable Gearboxes

Yes, there are several types of variable gearboxes available:

- Continuously Variable Transmissions (CVTs): These use a belt or chain running between two pulleys with variable diameters. By adjusting the pulley diameters, the gear ratio can be varied smoothly.

- Hydrostatic Transmissions: These use hydraulic pumps and motors to control the speed and torque of the output shaft. By varying the displacement of the pump or motor, the gear ratio can be adjusted.

- Infinitely Variable Transmissions (IVTs): Similar to CVTs, IVTs offer continuous variation of the gear ratio. They often use a combination of planetary gear sets and hydraulic components.

- Electronic Variable Transmissions (EVTs): These use electronic control systems to continuously adjust the gear ratio based on input from sensors and the vehicle’s operating conditions.

These types of variable gearboxes offer different mechanisms for adjusting the gear ratio, each with its advantages and applications.

Effect of Different Load Conditions on a Variable Gearbox

The performance of a variable gearbox can be significantly influenced by various load conditions. Here’s how different load conditions can affect a variable gearbox:

- Light Loads: Under light load conditions, a variable gearbox may operate at lower torque levels. This can lead to higher efficiency and reduced wear and tear on components, resulting in smoother operation and potentially improved fuel efficiency.

- Normal Loads: Operating within the designed load range of the gearbox ensures optimal performance and efficiency. The gearbox can adapt to changes in load and provide the appropriate gear ratio for efficient power transmission.

- Heavy Loads: When subjected to heavy loads, a variable gearbox may experience increased stress and higher torque demands. While the gearbox can adapt and provide higher torque output, it may also generate more heat and experience greater wear, potentially affecting its longevity if not properly managed.

- Variable Loads: In applications with varying loads, a well-designed variable gearbox can provide continuous adjustment of the gear ratio to match the changing demands. This flexibility can enhance overall efficiency and prevent strain on the gearbox.

- Overloads: Operating the gearbox beyond its rated capacity or experiencing sudden spikes in load can lead to excessive wear, reduced efficiency, and potential overheating. It’s important to avoid overloading the gearbox to ensure its longevity.

In summary, different load conditions can impact the performance, efficiency, and durability of a variable gearbox. Properly managing and selecting the appropriate gear ratios for specific load conditions can help optimize its operation and maximize its lifespan.

Improving Energy Efficiency with a Variable Gearbox

A variable gearbox, like a Continuously Variable Transmission (CVT), can enhance energy efficiency by allowing the engine to operate at its optimal RPM range, irrespective of the vehicle’s speed. This eliminates inefficient gear changes and reduces the engine’s workload during acceleration. The CVT’s stepless gear ratio adjustments enable the engine to maintain a constant and efficient power delivery, resulting in better fuel economy. Additionally, the CVT’s ability to adapt to different driving conditions ensures that the engine operates at the most efficient RPM, further contributing to fuel savings.

editor by CX 2024-03-27