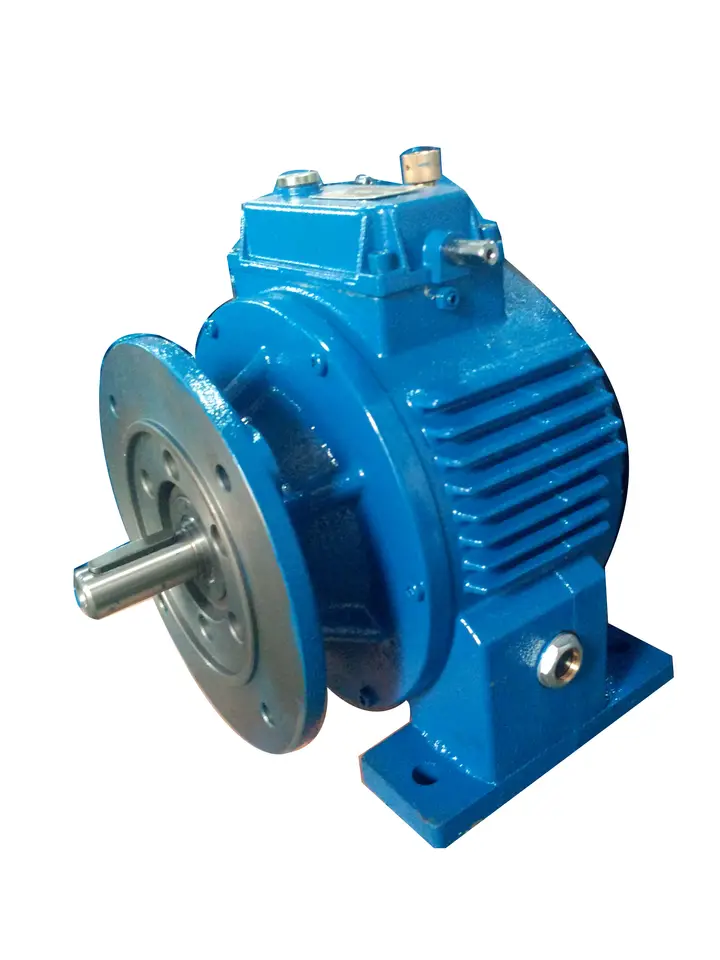

Product Description

1) High precision of speed regulating for speed variator,UD gear box: up to 0.5-1 round

2) Large speed-changing range: the speed ratio ranges from 1:1.4 to 1:7 freely

3) High intensity and long serving time

4) Convenient to regulate speed

5) Continuously workable, bidirectional working direction,smooth running,

stable, and quiet

6) Fully sealed and suitable to any environment

7) Compact structure, small size

8) High quality aluminum alloy die-cast, elegant shape, light weight and non-rusting

9) Good adaptability: can be combined with all kinds of reducers to achieve low

stepless speed changing

10) Input power: 0.18-7.5kW

| Power | Model | I | n2(r/min) | M2(NM) |

| 0.18kw | UDL0.18 | 1.6-8.2 | 880-170 | 1.5~3 |

| 0.37kw | UDL0.37 | 1.4-7 | 1000-200 | 3~6 |

| 0.55kw | UDL0.55 | 1.4-7 | 1000-200 | 4~8 |

| 0.75kw | UDL0.75 | 1.4-7 | 1000-200 | 6~12 |

| 1.1kw | UD1.1 | 1.4-7 | 1000-200 | 9~18 |

| 1.5kw | UD1.5 | 1.4-7 | 1000-200 | 12~24 |

| 2.2kw | UD2.2 | 1.4-7 | 1000-200 | 18~36 |

| 3kw | UD3 | 1.4-7 | 1000-200 | 24~48 |

| 4kw | UD4 | 1.4-7 | 1000-200 | 32-64 |

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Mounting: | Foot Mounting/Flange Mounting |

|---|---|

| Color: | Blue/Silver White |

| Oil Seal: | Nak Oil Seal |

| Customization: |

Available

| Customized Request |

|---|

Controlling Speed and Torque Output in a Variable Gearbox

In a variable gearbox, the speed and torque output are controlled by adjusting the transmission’s gear ratio. This is achieved through the manipulation of the pulley diameters in a Continuously Variable Transmission (CVT) or the swivel angle of the vanes in a hydrostatic transmission.

In a CVT, the pulley system consists of a primary pulley connected to the engine and a secondary pulley connected to the output shaft. By changing the effective diameter of these pulleys using hydraulic pressure or mechanical mechanisms, the gear ratio can be continuously adjusted. As the primary pulley diameter increases, the secondary pulley diameter decreases, and vice versa. This change in pulley diameters alters the gear ratio, affecting the speed and torque output.

In a hydrostatic transmission, the speed and torque output are controlled by adjusting the swivel angle of the vanes in the hydraulic pump and motor. When the swivel angle changes, the volume of fluid being pumped between the two components also changes, affecting the output speed and torque. This type of transmission offers stepless control of the gear ratio, making it suitable for applications that require precise speed and torque adjustments.

Lubrication Requirements for a Variable Gearbox

A variable gearbox, like any other gearbox, requires proper lubrication to ensure smooth operation and longevity. The type of lubrication needed depends on the specific design and components of the gearbox. Here’s what you should consider:

- Lubricant Type: The lubricant used should be compatible with the materials and components within the gearbox. High-quality transmission fluids or gear oils are commonly used for variable gearboxes.

- Viscosity: The viscosity of the lubricant is crucial for maintaining proper lubrication under different temperature conditions. The manufacturer’s recommendations or specifications should guide your choice of lubricant viscosity.

- Friction and Wear Protection: Variable gearboxes often have components that experience varying levels of friction. The lubricant should provide good wear protection and minimize friction to ensure efficient operation and minimize heat generation.

- Cooling Properties: Some variable gearboxes, especially those in heavy-duty applications, can generate significant heat. The lubricant should have effective cooling properties to dissipate heat and prevent overheating.

- Seal Compatibility: The lubricant should be compatible with any seals or gaskets in the gearbox, ensuring they remain effective in preventing fluid leaks.

- Regular Maintenance: Regular oil changes and maintenance are essential to keep the lubricant in optimal condition. Follow the manufacturer’s recommended maintenance schedule for oil changes and inspections.

It’s important to refer to the vehicle or equipment manufacturer’s recommendations for the specific lubricant type, viscosity, and maintenance schedule that best suit your variable gearbox. Proper lubrication will contribute to the gearbox’s smooth operation, efficiency, and overall longevity.

Common Industries Using Variable Gearboxes

Variable gearboxes, such as Continuously Variable Transmissions (CVTs), find applications in various industries. In the automotive sector, CVTs are widely used in passenger cars, motorcycles, and electric vehicles to improve fuel efficiency and optimize power delivery. They are also utilized in agricultural machinery, construction equipment, and industrial automation systems where precise control of speed and torque is crucial. Additionally, CVTs are employed in renewable energy systems, such as wind turbines, to efficiently convert varying rotational speeds into consistent energy output.

editor by CX 2023-09-28